Description

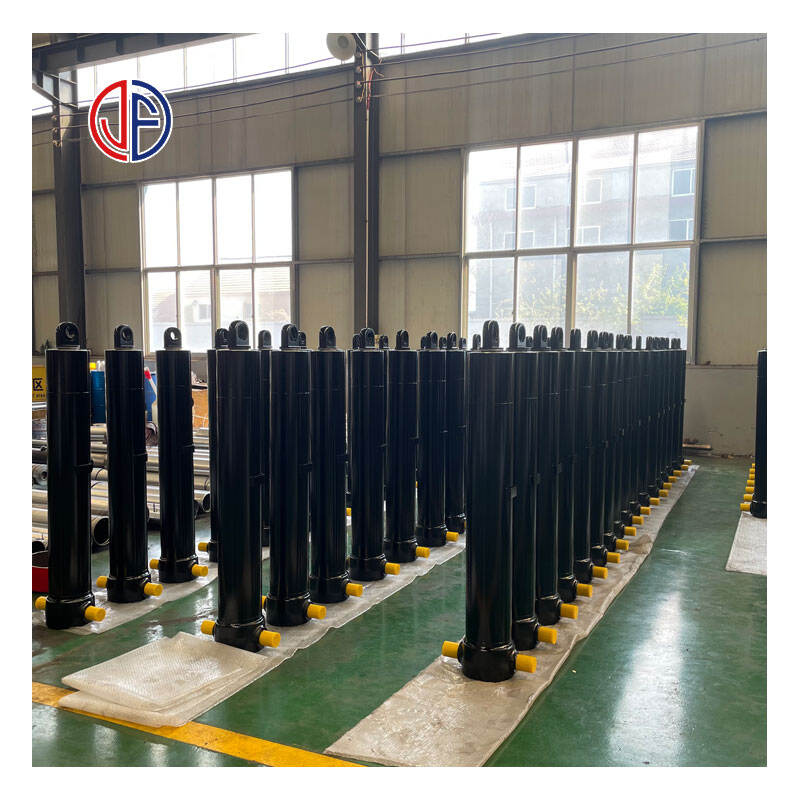

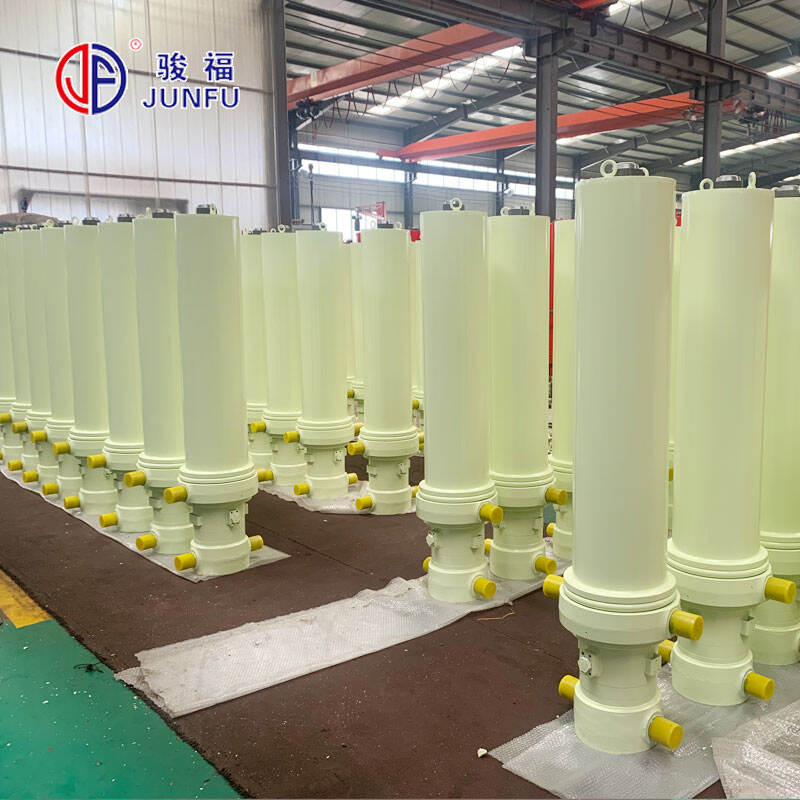

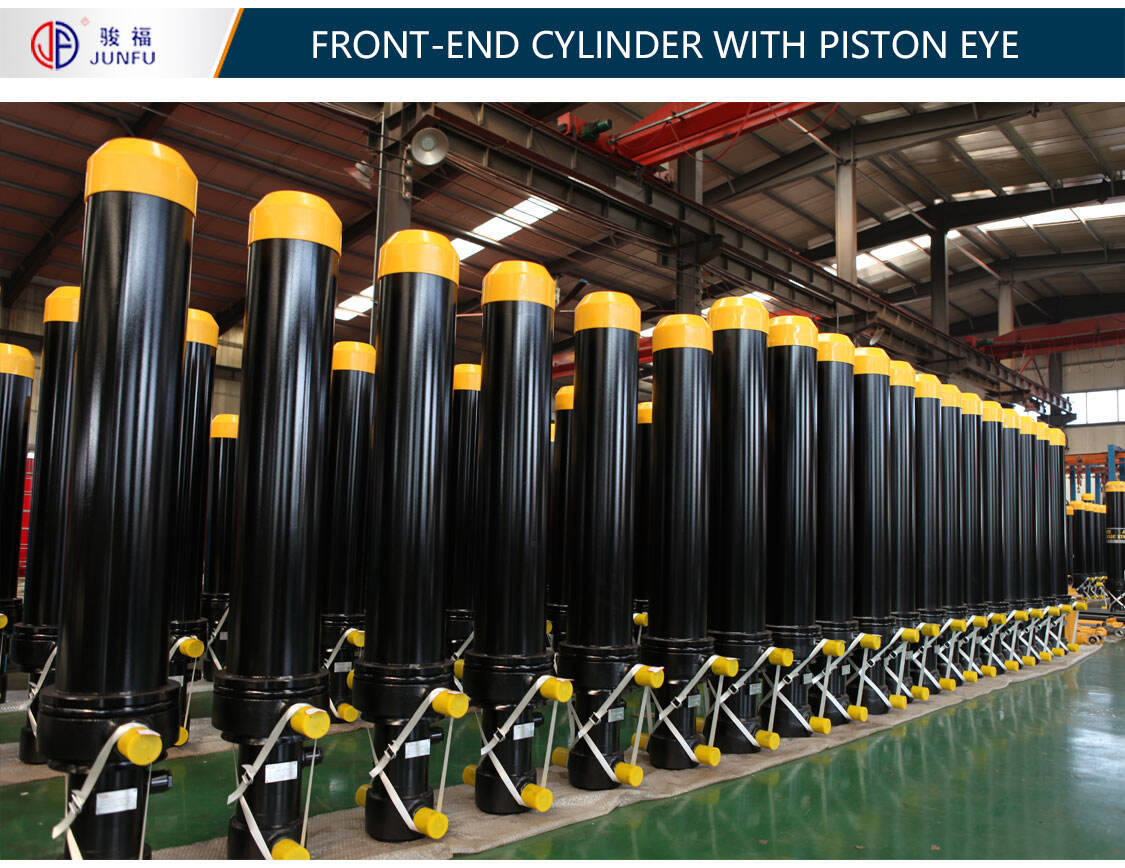

Introducing, the Junfu’s Single Acting Telescopic Hydraulic Cylinder Dump Truck Cylinder - a durable, reliable, and efficient solution for your hydraulic system needs. Junfu hydraulic is known for their high-quality products and innovative designs, and this cylinder is no exception.

With a single acting design, this telescopic hydraulic cylinder is perfect for dump truck applications, providing the power and precision necessary to handle heavy loads with ease. Whether you are lifting, hoisting, tilting, or dumping, this cylinder delivers smooth and consistent performance every time.

Constructed from durable materials, this cylinder is built to withstand the toughest conditions. The high-strength steel body and chrome-plated rod ensure long-lasting durability and resistance to corrosion, while the multiple stages of extension allow for increased reach and versatility.

Easy to install and operate, this hydraulic cylinder is designed for maximum efficiency and minimal maintenance. The sealed construction prevents leaks and contamination, while the built-in bypass valve provides added safety and protection. With a high quality hydraulic fluid, you can expect smooth and reliable operation, reducing downtime and increasing productivity.

This Junfu hydraulic’s cylinder is designed to meet the highest standards of quality and performance, making it an ideal choice for professionals and DIY enthusiasts alike. Whether you are working in construction, agriculture, mining, or any other industry that requires heavy lifting, this cylinder is sure to impress.

The Junfu’s Single Acting Telescopic Hydraulic Cylinder Dump Truck Cylinder is a top-of-the-line product that offers exceptional value and performance. With its durable construction, efficient design, and reliable operation, this cylinder is a must-have for anyone in need of a high-quality hydraulic solution. Trust Junfu hydraulic to provide you with the best products on the market, and experience the difference for yourself

Type |

Cylinder diameter

- mm

|

Rated pressure

- MPA

|

Installation distance

- mm

|

Stroke

- mm

|

Total length - mm |

Weight

- kg

|

||||||

FC129-3-3220 |

129 |

22 |

343 |

3220 |

1387 |

191 |

||||||

FC129-4-3480 |

129 |

22 |

343 |

3480 |

1218 |

178 |

||||||

FC137-3-3830 |

137 |

22 |

343 |

3830 |

1640 |

244 |

||||||

FC137-3-4280 |

137 |

22 |

343 |

4280 |

1860 |

268 |

||||||

FC137-4-4280 |

137 |

22 |

343 |

4280 |

1455 |

236 |

||||||

FC157-4-3830 |

157 |

22 |

343 |

3830 |

1350 |

260 |

||||||

FC157-4-4650 |

157 |

22 |

343 |

4650 |

1555 |

280 |

||||||

FC157-4-5000 |

157 |

22 |

343 |

5000 |

1650 |

300 |

||||||

FC157-5-3830 |

157 |

22 |

343 |

3830 |

1170 |

230 |

||||||

FC157-5-4650 |

157 |

22 |

343 |

4650 |

1275 |

245 |

||||||

FC179-4-4280 |

179 |

22 |

343 |

4280 |

1480 |

235 |

||||||

FC179-4-5390 |

179 |

22 |

343 |

5390 |

1755 |

360 |

||||||

FC179-4-6100 |

179 |

22 |

343 |

6100 |

1940 |

390 |

||||||

FC179-5-3830 |

179 |

22 |

343 |

3830 |

1170 |

265 |

||||||

FC179-5-4650 |

179 |

22 |

343 |

4650 |

1282 |

283 |

||||||

FC179-5-5000 |

179 |

22 |

343 |

5000 |

1405 |

305 |

||||||

FC179-5-5800 |

179 |

22 |

343 |

5800 |

1570 |

350 |

||||||

FC179-5-6300 |

179 |

22 |

343 |

6300 |

1655 |

360 |

||||||

FC179-5-7300 |

179 |

22 |

343 |

7300 |

1850 |

400 |

||||||

FC191-5-5780 |

191 |

22 |

343 |

5780 |

1530 |

273 |

||||||

FC191-5-6500 |

191 |

22 |

343 |

6500 |

1670 |

410 |

||||||

FC191-5-6800 |

191 |

22 |

343 |

6800 |

1735 |

738 |

||||||

FC191-5-7300 |

191 |

22 |

343 |

7300 |

1835 |

458 |

||||||

FC191-54-6100 |

191 |

22 |

343 |

6100 |

1955 |

273 |

||||||

FC196-4-6180 |

196 |

22 |

343 |

6180 |

1940 |

479 |

||||||

FC196-5-6350 |

196 |

22 |

343 |

6350 |

1710 |

450 |

||||||

FC202-4-6100 |

202 |

22 |

343 |

6100 |

1935 |

479 |

||||||

FC202-5-6800 |

202 |

22 |

343 |

6800 |

1765 |

465 |

||||||

FC202-6-7000 |

202 |

22 |

343 |

7000 |

1570 |

440 |

||||||

FC214-5-7300 |

214 |

22 |

343 |

7300 |

1900 |

530 |

||||||

FC214-7-7600 |

214 |

22 |

343 |

7600 |

1455 |

450 |

||||||

FC240-5-9030 |

240 |

22 |

343 |

9030 |

2270 |

820 |

||||||

Pipe dia: 202/179/157/137/118/99/80

240/214/191/169/149/129/110/90/70

|

||||||||||||

2. faster unloading

Junfu series oil cylinder adopts excellent structural design to improve the unloading speed of the oil cylinder

3. higher lift frequency

Junfu series oil cylinders are suitable for all-weather short barge and high-frequency operations, with stable performance, extremely low failure rate, increasing the number of transfers and reducing downtime

4. Greater adaptability to the environment

Junfu series oil cylinder adopts innovative sealing technology and new material application, which can adapt to the temperature range of -40~110ºC, and can achieve excellent performance in high temperature and low temperature environment operation

5. lighter

Compared with other products of the same series, Junfu series cylinders reduce the dead weight by 15%~20%, and increase the lifting force by 10%~15%

6. Greater lifting force

Compared with other products of the same series, the lifting force of junfu series cylinders is increased by 10%~15%. More lift, more load, more profit! Lighter dead weight, greater lifting force, more lightness

1. Trial Operation Test

2. Start-up Pressure Test

3. Pressure-Tight Test

4. Leak Test

5. Full Stroke Test

6. Buffer Test

7. Testing the Effect of Limit

8. Load Efficiency Test

9. Reliability TestEvery piece hydraulic cylinder will be tested before deliver

One year warranty, full life service

Q2: What's your cylinder's advantages

The cylinders are manufactured by advanced equipments and made under strictly quality control processing

The steel is tempered and all raw materials are good quality from world famous companies

Competitive price

Q3: When your company be established

Our company be established in 2002, professional manufacturer of hydraulic cylinders more than 20 years

We had passed IATF 16949:2016 Quality control system, ISO9001, CE

Q4: How about the delivery time

30 days approximately