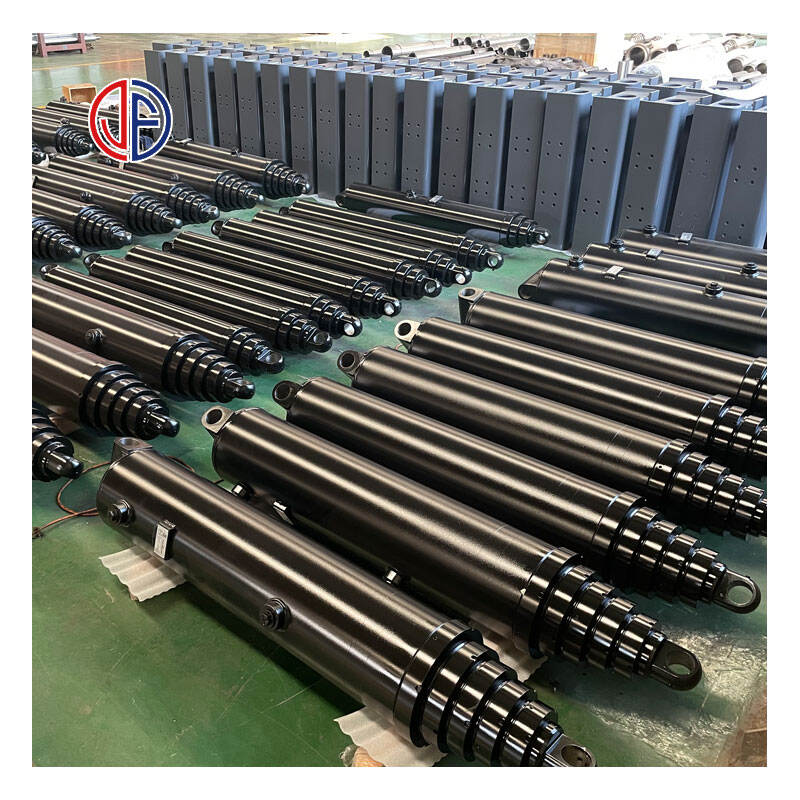

Rebuilding a hydraulic cylinder can be a bit of a head-scratchier, but it’s not something you can’t handle if you have the right machines, tools and patience. Machines that assist in raising, pushing or pulling heavy objects use hydraulic cylinders. They operate by way of fluid under pressure, and in some cases they can fail or develop leaks. It’s worth it to try and repair them, rather than buy new ones. With Junfu Hydraulic's quality products and team of professionals, you can rehabilitate your hydraulic cylinder to ensure that it operates like it did when brand new. This guide will explain what you need and how to do it, one step at a time.

What You Should Consider For Rebuilding a Hydraulic Cylinder To Increase Performance

When you’re ready to rebuild a hydraulic cylinder, the first thing to think about is how it operated in the first place. This will provide some insight into what could be going wrong. Begin by carefully disassembling everything. You need to check for scratches or any damage on the cylinder rods and seals. If you can see scratches, that is maybe a signal the cylinder will not work fine after a rebuilding. You’ll want to inspect of seals to see if any are tough or dried and cracked. These parts help prevent the fluid from escaping so that the pressure accumulates as it should. Occasionally you will also find dirt and trash up in the cylinder. This is a big red flag! You need to clear it out entirely before you can add new parts in. An O-ring is a common component you may need to replace. Leaky sealing An O-ring that’s worn out will lead to leaks. If you notice them with wear tear, replace them with good-quality from Junfu Hydraulic. Keep in mind, when selecting a trusted brand is crucial to restoring the right shape properly. Simply remember while rebuilding, that all your connections are secure, you don't want any problems later on. Reassemble after resetting the cylinder, fill with new hydraulic fluid and let it sit a moment before testing. In this manner, bubbles are encouraged to rise through the fluid and you have a better chance of smooth operation. Restoring a hydraulic cylinder to the desired clean packing and working well, can be rewarding when you see it operating like new.

Where to Get the Best Quality Wholesale Hydraulic Cylinder Rebuild Part Suppliers

It can be difficult to locate parts to rebuild hydraulic cylinder, but Junfu Hydraulic has some great options for you. If you want quality parts at a wholesale price, we are your best option. We have a variety of seals, O-rings and other necessary parts for various hydraulic cylinders. When you invest in us, you're not only saving money, you're also getting pieces of exceptional quality. You can also visit our store or check out our website. You can find everything you need to keep your project running on there. It’s like shopping in a beautifully arranged toolbox everything that you need is exactly where it belongs! If you’re interested in specific segments of it, you can also speak with our friendly team for guidance. They can help you select the perfect ingredients for your specific purpose. And if you are purchasing by the case, be sure to inquire about discounts on bulk orders. This is where you can really get value for your money. Quality parts are paramount to ensuring your hydraulic cylinder works once you rebuild it. You don’t want to take any shortcuts when it comes to safety and performance. You can also look through local suppliers or online marketplaces, but read reviews as well. You want guarantee that they come with a good reputation. Brake Hydraulic Parts When it comes to your brake hydraulic parts, don't skimp on safety: 'the cheaper the better' can backfire. With Junfu Hydraulic, you are bound to have the perfect happy shopping.

Step-by-Step Guide to Rebuilding and Resealing a Hydraulic Cylinder

Rebuilding a hydraulic cylinder can be much easier one would ever think. Knowing the basics on how to rebuild a hydraulic cylinder is the first step toward performing the repair correctly. When you begin, make sure you have the proper tools. You will need wrenches, a socket set and possibly some pliers. You should also be wearing goggles and gloves to protect yourself. First step (critical is to take the hydraulic cylinder out of the machine. This typically means unscrewing bolts or nuts that keep it in place. Once it’s free, you can carry it over to your workspace. The second step is to remove the Hyd. It can be a messy fluid, so make sure you have rags nearby to catch spills. Once drained, unscrew the end caps of cylinder with your drivers. When the caps are removed, you can extract the piston and rod. Wipe all components down with a clean rag to remove any dirt and old fluid. Once clean check the parts for wear of damage. If you see any scratches or dents, these components may be replacement candidates. Next, you’ll want to replace the seals on the piston. The seals are critical to prevent hydraulic fluids from leaking. Note that you should check the sizes and purchase accordingly seals for your cylinder. Once you’ve got your new seals, be sure to install them carefully so that they don’t rip or tear. Then, slide the piston back into the cylinder. Once everything is all put back together, be sure to reattach the end caps securely to prevent any leaking of fluids. Then, fill the cylinder with fresh hydraulic fluid and inspect for leaks. If there are no leaks, you’ve successfully resealed the hydraulic cylinder.

How to Maintain a Rebuilt Hydraulic Cylinder for Long-Term Performance

After you rebuild your hydraulic cylinder, you want to keep it going for as long as possible and that means good care and maintenance. First, monitor the level of fluid in the tank as part of your regular maintenance; low fluid can cause the cylinder to exert more force and wear out sooner. Using the correct type of hydraulic fluid is also important; every system has its own requirements. Take the manufacturer’s recommendation, especially if you have Junfu hydraulic products. Another thriving secret is checking the hydraulic cylinder on a regular basis. Inspect for any wear and leaking seals. If you do see problems, address them now before they get worse. And it’s also crucial to keep the cylinder clean. Dust and dirt may erode parts over time. Keep the cylinder and local area wiped down with a damp cloth routinely. It's also best to not run the hydraulic system at temps on either end of the scale as well. Performance may be affected if used in temperatures nearing the temperature range. When you are done, store it indoors in a temperature controlled environment to prevent weather damage when not in use. It’s also necessary to know how to use your machinery the right way. Avoid over sizing and abusing a hydraulic system, as this might cause faster deterioration. If you maintain your hydraulic cylinder, which means carrying out the installation correctly and following proper procedures, it will live a much longer life. It bears repeating, you are trying to create an efficient hydraulic system for as long a term as you can.

Common Hydraulic System Problems and How to Troubleshoot Them

There are times when rebuilding your hydraulic system doesn't even solve your problems. It’s essential to learn how to solve these common problems. The overwhelming majority of problems are leaks. If hydraulic fluid ends up on the outside of the piston, it might indicate that either the seals were improperly installed or are faulty. Check for the seals that make sure they are seated correctly. Another possibility might be that the cylinder isn’t traveling properly. If the plunger does not slide in and out, freely, check for obstructions inside the cylinder. Dust or dirt may be clogging it, impeding smooth streetcar operation. Also check to see that hydraulic fluid is at the correct level. If the fluid’s level is too low, it won’t generate enough pressure to push the piston. You may hear strange sound in the time of using hydraulic mechanism. This may be a result of there still being air in the system possibly from not bleeding it after refilling with fluid. To remedy this, you may just need to bleed the hydraulic system until all of the air is gone. And second, if the cylinder is functioning but has less power than it had before, this might be suggesting internal wear. You may have to dismantle the cylinder again to check parts like the piston for wear. Note that it’s fine to ask for help if you‘re stumped. Another approach is sometimes the best. Call in outside experts, especially if problems linger. Junfu hydraulic is ready to help you and serve your if you have any problems of hydraulic solved.

Table of Contents

- What You Should Consider For Rebuilding a Hydraulic Cylinder To Increase Performance

- Where to Get the Best Quality Wholesale Hydraulic Cylinder Rebuild Part Suppliers

- Step-by-Step Guide to Rebuilding and Resealing a Hydraulic Cylinder

- How to Maintain a Rebuilt Hydraulic Cylinder for Long-Term Performance

- Common Hydraulic System Problems and How to Troubleshoot Them