Telescopic hydraulic cylinder is a prevalent component in heavy duty vehicles such as dump trucks, cranes and excavators. These hydraulics components are critical for the delivery of the power and force expected to be applied by machinery. When selecting the correct hydraulic control valve telescopic for your equipment there are a number of factors to be taken into consideration in order to achieve success and longevity.

When choosing a hydraulic telescopic cylinder, you need to take into account maximum operating pressure, stroke length and bore size as well as the mounting style. The working pressure suitable to your machinery should be less than 0.7Mpa(7bar). The maximum ET of the cylinder is determined by the stroke length, whereas the bore size refers to the diameter. Furthermore, selecting the appropriate side mounted hydraulic tank mounting options are vital to making your installation as simple as possible and affordable.

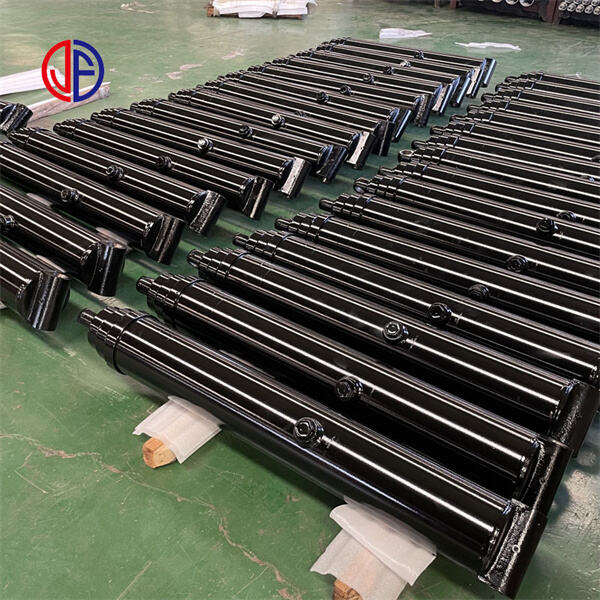

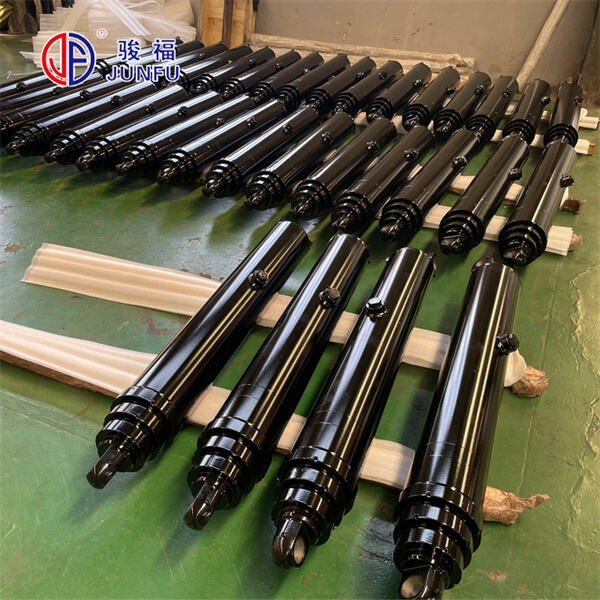

HLQK Type Junfu Hydraulic develops the telescopic hydraulic cylinder covering single-acting and double-acting series for different industrial sectors. We have a broad product offering that includes single-acting, double-acting, and multi-stage telescopic hydraulic cylinders to ensure you get the most appropriate product for the task at hand. Whether you require off the shelf cylinders or a solution tailored to your specific requirements, we offer competitive wholesale solutions for all of your machinery's needs.

Hydraulic cylinder telescopic are essential for heavy equipment in which the force needs to be multiplied using hydraulics at a minimum amount of stroke. These cylinders can withstand direct exposure to high-pressure, and also large capacity break-even conditions, so that they are well-suited for rugged applications in industry, agriculture and transportation. Heavy-duty machinery can be effectively, safely and reliably work in variety of working condition by the application of hydraulic cylinder one way telescopic.

Last advances in hydraulic cylinder telescopic technology are concentrating on optimising efficiency, strength and precision of actions in industrial application. New technologies, including special sealing materials and position sensors integration (even corrosion protections) have improved efficiency and life time.cylinders. Furthermore, the incorporation of smart functions and automation features have provided remote monitoring as well as predictive maintenance of hydraulic systems to help maximise machine availability.

Copyright © Shandong Junfu Hydraulic Technology Co.,Ltd All Rights Reserved | Privacy Policy